1 - 6

MELSEC-Q

1 PRODUCT OUTLINE

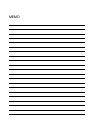

Lifter (Storage of Braun tubes onto aging rack)

PLC MELSEC-Q

Servo

amplifier

Servomotor

Aging rack

Lifter

Counter-

weight

A conveyor

Servo

amplifier

Reduction

gears

Servomotor

(with brakes)

QD75MH

B conveyor

C conveyor

G2

G1

Loader/unloader

Unloader

Loader

•

During the aging process of Braun tubes,

storage onto the rack is carried out by

positioning with the AC servo.

•

The up/down positioning of the lifter is carried

out with the 1-axis servo, and the horizontal

position of the aging rack is positioned with the

2-axis servo.

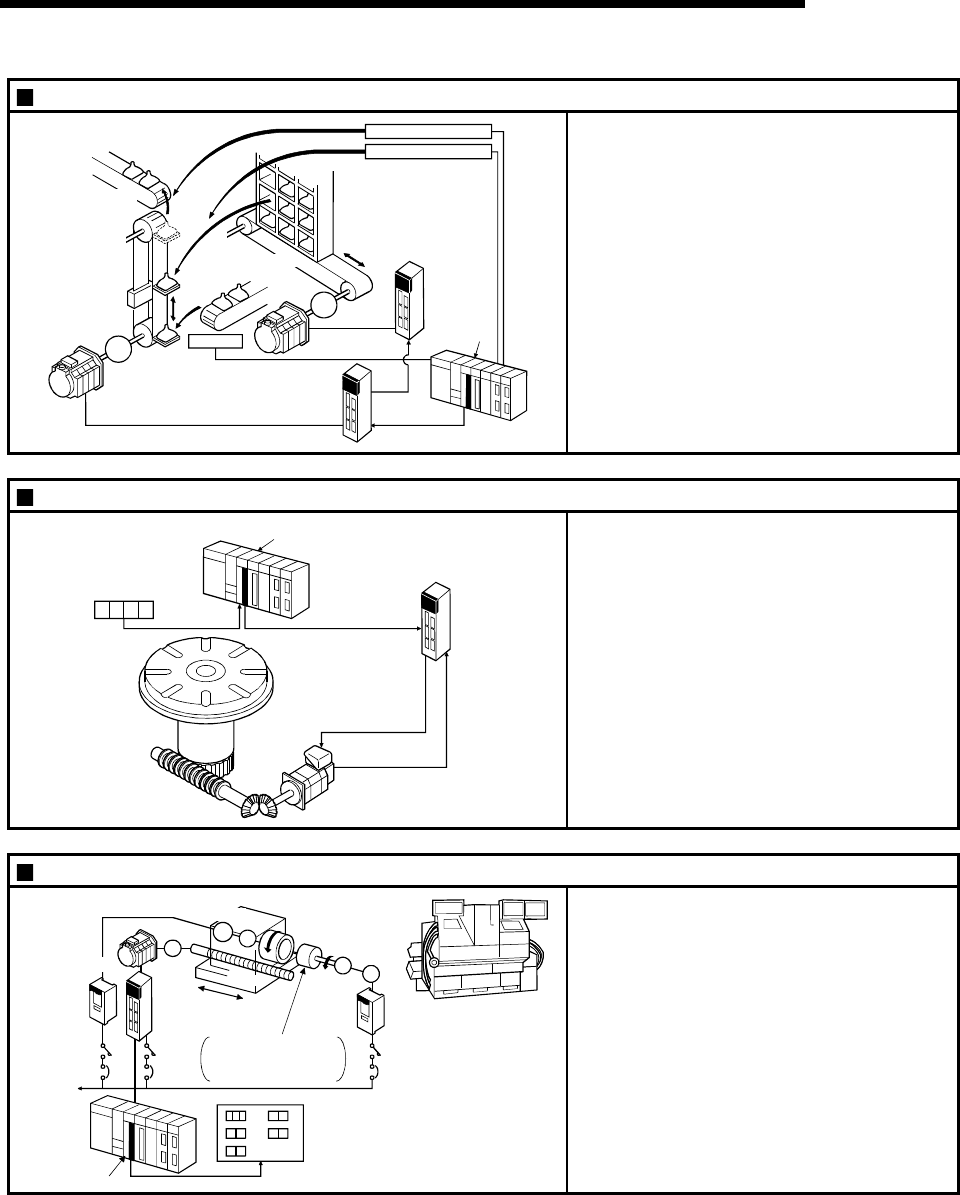

Index table (High-accuracy indexing of angle)

Detector

Servomotor

Worm gears

Index table

Digital switch

PLC

MELSEC-Q

Servo

amplifie

r

QD75MH

•

The index table is positioned at a high accuracy

using the 1-axis servo.

Inner surface grinder

PLC

MELSEC-Q

QD75MH

Servomotor

Servo

amplifier

220VAC

60Hz

Inverter

Grinding stone

Workpiece

Motor

Fix the grinding

stone, feed the

workpiece, and grind.

Operation panel

a. Total feed

amount (

µ

m)

b. Finishing

feed amount (µm)

c. Compensation

amount (µm)

d. Rough grind-

ing speed (

µ

m/s)

e. Fine grinding

speed (µm/s)

Inverter

G

IM

G

a

b

c

d

e

Motor

IM

G

•

The grinding of the workpiece's inner surface

is controlled with the servo and inverter.

•

The rotation of the workpiece is controlled with

the 1-axis inverter, and the rotation of the

grinding stone is controlled with the 2-axis

inverter. The workpiece is fed and ground with

the 3-axis servo.