5 - 29

MELSEC-Q

5 DATA USED FOR POSITIONING CONTROL

[Table 1]

Pr.1

setting value

Value set with peripheral device (unit) Value set with PLC program (unit)

0 : mm 0.01 to 20000000.00 (mm/min)

1 to 2000000000 (×10

-2

mm/min)

1 : inch 0.001 to 2000000.000 (inch/min)

1 to 2000000000 (×10

-3

inch/min)

2 : degree 0.001 to 2000000.000 (degree/min)

1

1 to 2000000000 (×10

-3

degree/min)

2

3 : PLS 1 to 50000000 (PLS/s) 1 to 50000000 (PLS/s)

1: The speed limit value setting range is 0.001 to 2000000.000[degree/min], but it will be decupled

and become 0.01 to 20000000.00[degree/min] by setting "

Pr.83

Speed control 10 x multiplier

setting for degree axis" to valid.

2: The speed limit value setting range is 1 to 2000000000(

×

10

-3

degree/min), but it will be decupled

and become 1 to 2000000000 (

×

10

-2

degree/min) by setting "

Pr.83

Speed control 10 x multiplier

setting for degree axis" to valid.

Pr.8

Speed limit value

Set the maximum speed during positioning and OPR operations.

The maximum speed during positioning control has to be limited in consideration

of the drive unit and control target specifications.

Take account of the following when determining the speed limit value:

1) Motor speed

2) Workpiece movement speed

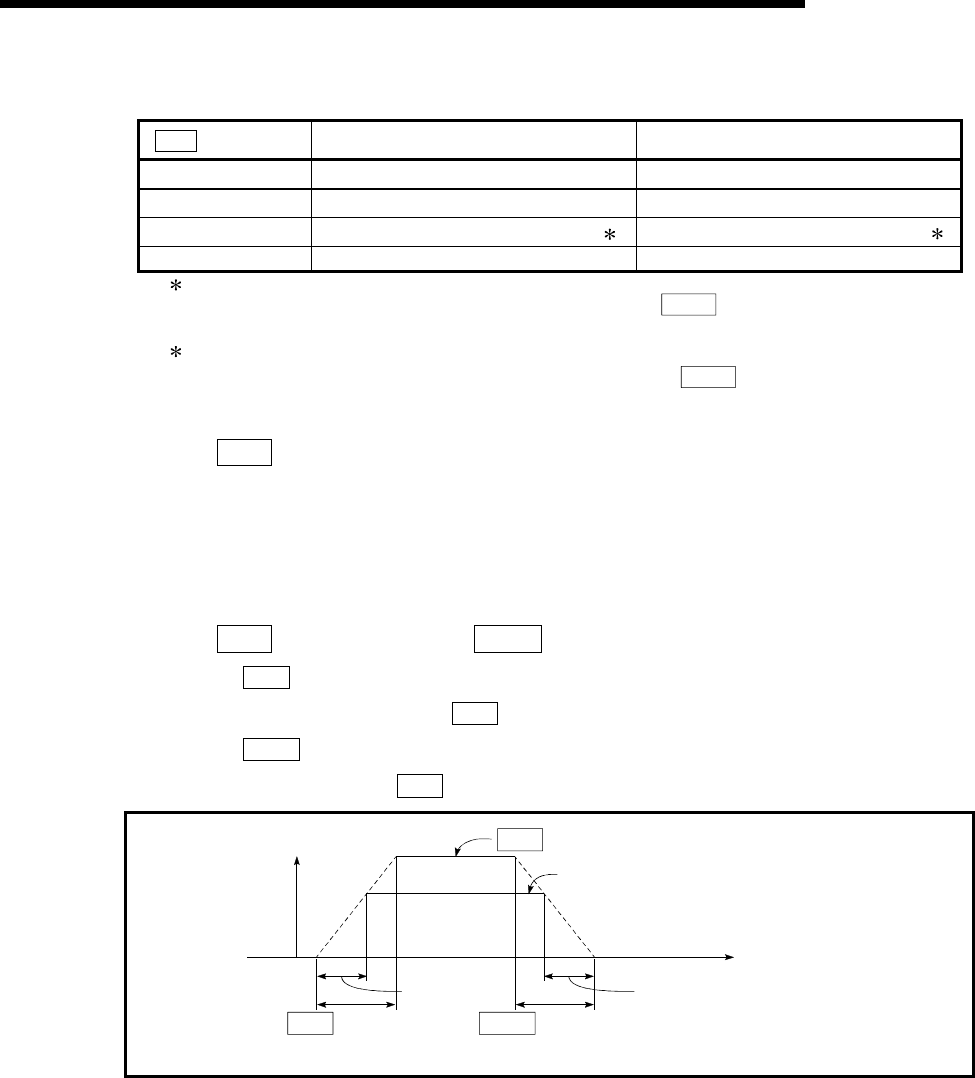

Pr.9

Acceleration time 0,

Pr.10

Deceleration time 0

"

Pr.9

Acceleration time 0" specifies the time for the speed to increase from zero

to the speed limit value (

Pr.8

).

"

Pr.10

Deceleration time 0" specifies the time for the speed to decrease from the

speed limit value (

Pr.8

) to zero.

Actual

acceleration

time

Actual deceleration time

Time

Velocity

Speed limit value

Positioning speed

Acceleration time 0

Pr.9

Pr.10

Pr.8

Deceleration time 0

1) If the positioning speed is set lower than the parameter-defined speed limit

value, the actual acceleration/deceleration time will be relatively short. Thus,

set the maximum positioning speed equal to or only a little lower than the

parameter-defined speed limit value.

2) These settings are valid for OPR, positioning and JOG operations.

3) When the positioning involves interpolation, the acceleration/deceleration time

defined for the reference axis is valid.