15 - 49

MELSEC-Q

15 TROUBLESHOOTING

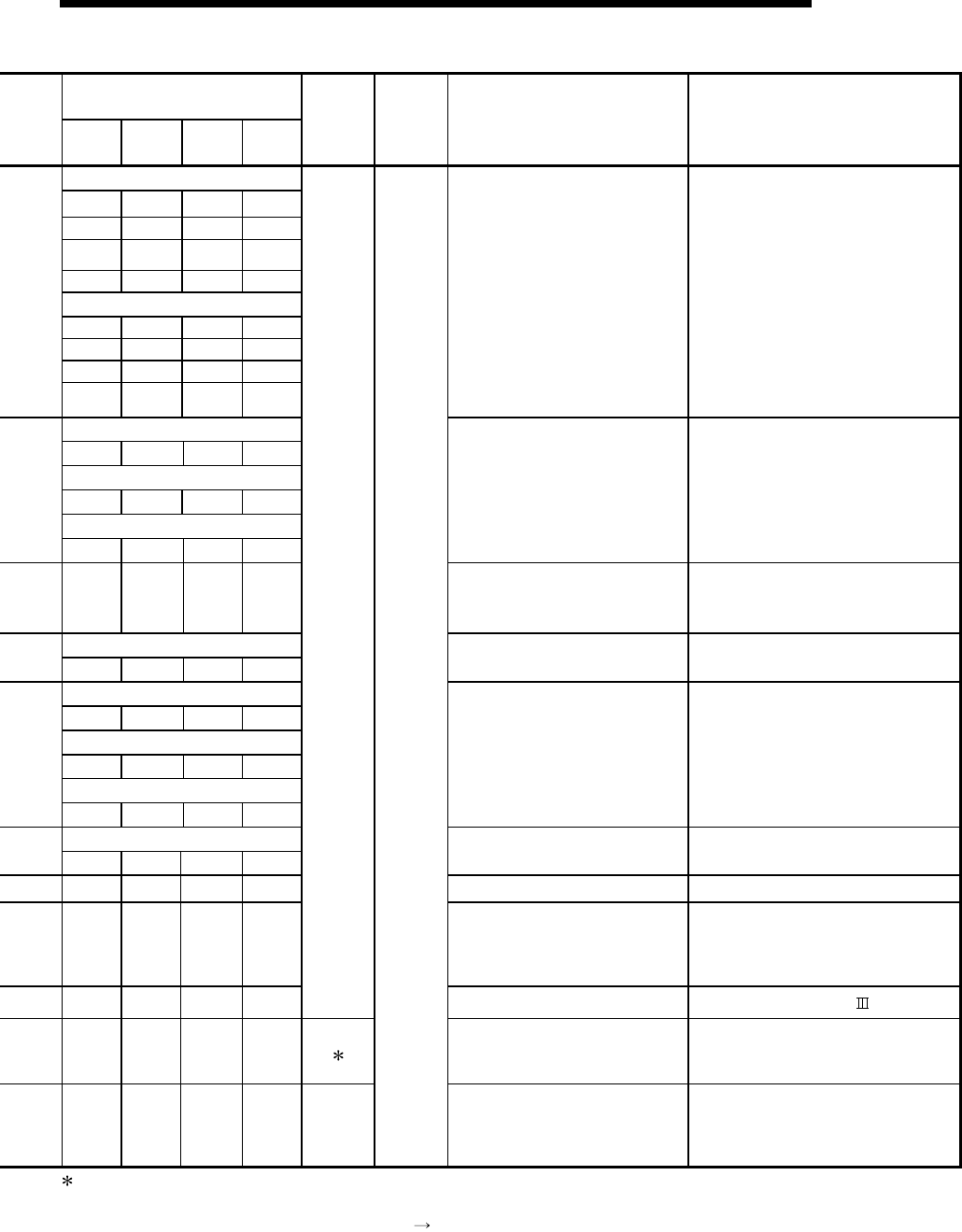

Related buffer memory address

Axis 1 Axis 2 Axis 3 Axis 4

Error

check

timing

Error

process-

ing

Check point Corrective action

Acceleration time

12, 13 162, 163 312, 313 462, 463

36, 37 186, 187 336, 337 486, 487

38, 39 188, 189 338, 339 488, 489

40, 41 190, 191 340, 341 490, 491

Deceleration time

14, 15 164, 165 314, 315 464, 465

42, 43 192, 193 342, 343 492, 493

44, 45 194, 195 344, 345 494, 495

46, 47 196, 197 346, 347 496, 497

Increase the

acceleration/deceleration time

constant.

Torque limit value

26 176 326 476

OPR torque limit value

86 236 386 536

Torque output setting value

1552 1652 1752 1852

Increase the torque limit value.

— — — —

• Review the power supply capacity.

• Use servomotor which provides

larger output.

Model loop gain

30125 30325 30525 30725

Increase set value and adjust to

ensure proper operation.

Torque limit value

26 176 326 476

OPR torque limit value

86 236 386 536

Torque output setting value

1552 1652 1752 1852

• When torque is limited, increase

the limit value.

• Reduce load.

• Use servomotor that provides

larger output.

Input signal logic selection

31 181 331 481

• Review operation pattern.

• Install limit switches.

— — — —

Change the servomotor.

— — — —

Connect correctly.

— — — —

Always

Change the SSCNET

cable.

— — — —

Use correct combination.

— — — — Always

Imme-

date stop

Servo amplifier error (2088)

occurs if power is switched on

after disconnection of the

CN1A

,

CN1B and CN3

Change servo amplifier.

:

The error check timing is shown below.

• When servo amplifier is power ON.

• When the QD75MH detects the rising edge (OFF

ON) of the PLC READY signal [Y0].

• When servo amplifier is reset.

• When the QD75MH is power ON.